Table of Contents

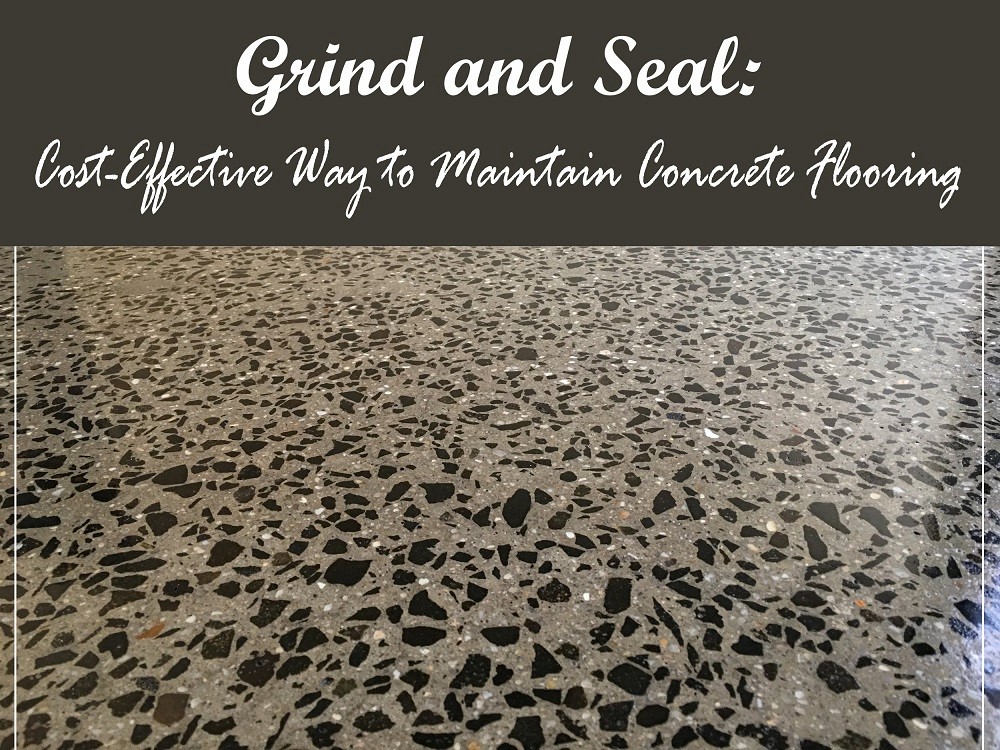

Concrete floors are trending currently as they provide a durable surface that is easy to maintain. Today, one will come across concrete flooring in both residential and commercial facilities. Most retailers, architects, and engineers prefer concrete as a flooring material and use grind and seal method to polish that dull looking floor into a stunning space.

Adding Sophistication with Grind and Seal:

Polished concrete floors enhance the look of the interiors and are suitable for a range of different spaces within commercial and residential buildings. The grind and seal method are not only practical but also cost-effective to polish the concrete. The porous concrete is treated with a chemical hardener before grinding it to get that smooth and glossy look with fine tools.

The depth of grind and seal is based on how much of the original surface is removed and exposed to get the desired effect. Thus, the floor surface is first ground and then sealed with a clear coating to add that protective layer.

The Grinding Process:

Grinding is a mechanical technique that smoothes out the surface of the concrete. The purpose of grinding is to get rid of any impurities or scratches or unevenness on the concrete surface layer. High high-powered concrete grinders are used to create exposure level to 800, 1500, or 3000 grit level.

The surface of the concrete is quickly and efficiently saturated and is commonly refined to100 grits. It has to be decontaminated before sealing, and proper grinding is a must before applying a sealant and polish on the surface.

Without grinding, it is not possible to get that uniformity and desired texture on the concrete surface.

The Sealing Process:

After grinding, a clear sealer is applied on the concrete surface to protect the concrete. The sealing is made of epoxy, acrylic, or urethane. There are different types of sealers based on their needs and budget. What you get after the sealing procedure is a more durable and smoother looking concrete surface which is easier to clean.

One can go for a matte or glossy sealing look, and the end result is a concrete floor that looks polished and glossy.

Benefits of Grind and Seal Floors:

The treated and sealed concrete surface is durable and resistant to any damage. Polished concrete is easy to clean and provides versatile looks because of the variety of the finishes that can mimic different looks of stone and ceramic. Colors and patterns can be added to get a different look with the polished floors.

One can work on the existing concrete floor without using any extra material. As the grind and seal procedure makes the concrete non-porous and resistant to wear and tear, it is a low maintenance floor. Thus, these methods are seen to be green because of their long life and low maintenance.

The treated concrete surfaces retain heat in summer and remain cool in winter.

One should not confuse grind and seal with grind and polish as there is a slight difference. Grind and polish are sued to develop a higher level of shine on the concrete surface. The grind and polish procedures are more expensive than the grind and seal methods. When looking for a grind and seal services, one should go with those that understand your need and are willing to work within your budget.

The final costs will rely on the area to be covered, the desired look of the floor and exposure level of the concrete. The kind of grind machine and type of sealant will rely on the needs of the space. Get referrals and read reviews before finalizing a professional for your project.